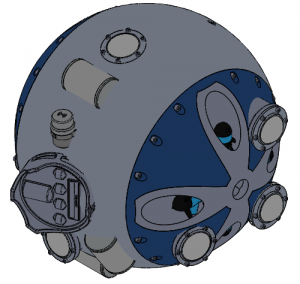

Thirteen organisations from seven countries across Europe are collaborating in an ambitious project to develop a submersible robotic system for surveying and exploration of flooded mines. The €5 million project, funded by the European Union’s Horizon 2020 research programme, includes the development of a Robotic Explorer (UX-1) for autonomous 3D mine mapping to gather valuable geological information that cannot be obtained in any other way; as the mines in question are too deep and dangerous to be accessed by human divers.

A multi-robot system based on UX-1 represents new technology, only made possible by recent developments in autonomy research which has allowed the development of a completely new class of robots, capable of operating underground without remote control: UX-1 will be the first of its kind. Research challenges are related to miniaturisation and adaptation of deep sea robotic technology to this new application environment and to the interpretation of high volumes of multivariate geoscientific data.

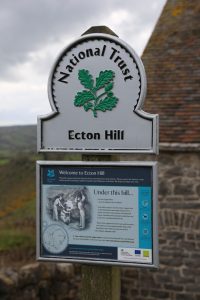

Pilot deployments will be carried out at mines with progressively more challenging conditions: Kaatiala feldspar/quartz mine (Finland), Idrija mercury mine (Slovenia) and Urgeiriça uranium mine (Portugal). The final, most ambitious demonstration will take place in the UK with the first modern survey of the Deep Ecton copper mine in Staffordshire. Most of this mine has been flooded and inaccessible for 160 years. These tests will demonstrate the system’s scalability from small missions to the largest ones by increasing the number of deployed autonomous drones and supporting multi-robot cooperation in confined 3D spaces with real-time sensor and data fusion for reliable navigation and communications.

© UNEXMIN Consortium

The development of UX-1 will open new exploration scenarios so that strategic decisions on re-opening Europe’s abandoned mines, many of which may still contain critical raw materials, can be underlain by real data, which cannot be gathered in any other way.

The last few months have set the ground for many developments, notably: UX-1’s hull design has been finalised and its manufacturing started in the autumn of 2017 and laboratory and real environment tests for the instrumentation units have been completed. This progress has allowed the team to move forward; prototypes are being developed and tested by the project’s technical teams. Software and hardware tools are being designed, developed and perfected. The first UX-1 prototype is being built and is scheduled to be ready by mid-2018, ready for the first field demonstration of the UNEXMIN project in the Kaatiala Mine, Finland.